I often think back to when I was a kid and watching my dad design his next woodworking project. Not only were his designs impressive, but they were all done with a pencil and a pad of notebook paper. May times, the finished product would vary significantly that these plans, though I’m not sure if that was based on the mental plans he had or if it was correcting problems from the design that was on paper.

Today, the tools available to design your next project has evolved considerably. Now, we have software available to use (for free!) that allows you to design a project, rotate and view it and in direction, and break it apart to shift parts around to different locations. This software also allows the user to find problems before they start cutting their wood which can save a significant amount of time, money and frustration. Nowadays, you can build a project in no time on the computer. There’s no longer a need to build prototype parts in an effort to figure out how to get parts to come together.

Below, I would cover the most popular woodworking software packages available to users today. I’ll provide some benefits to each in regards to a seasoned woodworking looking to dive into the CAD world to design projects.

Free and easy to use woodworking software has led to many other developments in the woodworking world that’s available to the average weekend hobbyist. Home built CNC routers have been extremely popular in recent years. I built one earlier this year and love it. For a complete overview of CNC routers, check out this article I recently wrote.

(Brief) Woodworking Software History

The most popular software on the market today is called SketchUp. The popularity of this program was driven by the fact that Google purchased the program and held if for about 6 years. Originally, the SketchUp was created by two programmers in Colorado who sold their creation to Google in 2006. Once Google took over, it became the primary CAD (Computer Aided Design) software on the market. After making numerous enhancements and changes, Google sold the program to a company called Trimble, Inc in 2012. Trimble still owns the program.

Prior to SketchUp, CAD software was typically only used by engineers. One reason for this was the cost of the software. Any decent program typically cost several hundred if not thousands of dollars to acquired. Then, once someone had a software package, the struggle became learning how to use it.

Prior to SketchUp, CAD software was typically only used by engineers. One reason for this was the cost of the software. Any decent program typically cost several hundred if not thousands of dollars to acquired. Then, once someone had a software package, the struggle became learning how to use it.

When Google released the free version of SketchUp in early 2007, it eliminated the costly upfront costs of purchasing the software. In addition, the growth in popularity of Youtube helped give new users access to endless hours of training by users uploading “How to” videos.

Using SketchUp

When you first use any CAD software for the first time it can be a bit overwhelming. For me, learning to rotate an object in a 3D setting was very confusing. It took some practice for me to grasp the concept of there being 3 planes to work with in a computer program. There is going to be a definite learning curve to any CAD program you choose. However, the general consensus is that SketchUp is the most user friendly woodworking software for 1st users.

It’s rather common for individuals to learn the basics of CAD design in this program and then move on to other programming options. That’s not to say It’s a bad program, just that some of the other software packages on the market offer more advanced features that may better suit your needs. Many people also choose to stay with SketchUp due because it easily handles everything they need.

I have links below for Youtube training videos, but personally, I like to have a physical books in hand sometimes when I’m learning the basics. There’s two good books on the market right now that are geared solely towards woodworkers using Sketchup. You can pick up both books on Amazon. The first is titled Sketchup Success for Woodworkers. The second book is called Sketchup – A Design Guide for Woodworkers.

If you are interested in learning either of the programs, check out my article “What Are The Best Resources To Learn CAD for Woodworking?”. I list several budget friendly options!

Benefits of SketchUp

- Price – When you first log onto their site, you may be shocked to see the sticker price of $695. This price is for those users who are using it for commercial purposes. SketchUp is completely free to those who use it for home, personal and educational use.

- Training Options – Since SketchUp was the first major CAD software to hit the market, there are endless options of training and how to videos available online. Here’s a link to an excellent set of SketchUp training videos on Youtube that is geared solely towards woodworking.

- Woodworking Plug-in’s – Another positive to using SketchUp are the plug-in’s that are available specifically for woodworkers. The most popular one in my opinion is called “Cut List.” Once you have designed your project, you can execute this plug-in and it will create a cut list of all parts in your project. This is super helpful by allowing you to have a quick and easy one page print out to take with you to buy your lumber as well as to have when you start cutting it.

- Community Files – The SketchUp community is huge. This community has a section called “3D Warehouse” which allows you to download free designs other members have created. Personally, I think this is a huge benefit for those just starting out in CAD software. This allows you to download existing projects, and play around with the different features of Sketchup. You can practice resizing items or changing their shape without having to build them from scratch.

Fusion 360

Fusion 360 was developed and is owned by a company called Autodesk. The company started back in 1982 and is currently traded on the Nasdaq exchange. In 2017, they reported sales of over $2 billion, so they are no small company. Autocad has been used in a wide range of  industries from designing buildings to cars. Fusion has become popular with woodworking and has actually been a significant reason for the recent growth in the home CNC sector of woodworking.

industries from designing buildings to cars. Fusion has become popular with woodworking and has actually been a significant reason for the recent growth in the home CNC sector of woodworking.

Fusion 360 was one of the first programs to tie product creation and CNC GCode generation together in a single package. In the past, users were required to export their creations from a CAD program into one that would create the code that would tell their routers and machines to move. Even if you aren’t looking to dive into the CNC world, there are benefits to using Fusion which we will outline below. The general consensus in the woodworking industry that have used both 360 and Sketchup is that 360 is a more powerful program with deeper features.

So far, I’ve only been able to find 1 book that is dedicated to woodworkers. It comes in a paperback or kindle edition on Amazon. I always elect for physical books so that I can have it and easily flip through. Here’s a link to the book.

For a general guide to Fusion 360, this book (also on Amazon) will do a great job of teaching you how to maneuver through the software. In the beginning, when you are learning a new program, it really doesn’t matter what you are building. Your focus should be learning how to move around in the software and how to do certain tasks.

Benefits of Fusion 360

- Price – The program is free if you are not planning to make money from your creations. Once you start earning income off your creations, commercial licenses start at $25 and increase up to $40 per month.

- Cloud based – Fusion has a small program that you will need to install that will sync files from your computer to the cloud. Otherwise, the software is cloud and web based which many users will find much easier and convenient to use.

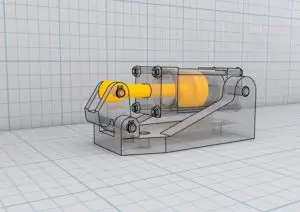

- CNC & 3D Printing options – This feature is what sets Fusion 360 apart from the other CAD programs. It is designed to work with CNC machines as well as 3D printing. So let’s say you create something in 360 and want to print it with a 3D printer. In SketchUp and most other programs, you will need to convert your design into the appropriate code for your CNC or printer to execute it properly. Fusion is able to do this conversion itself which saves you a few steps and is super easy to complete.

- Detailed Rendering – If you are designing pieces for your customers, it can be a huge advantage to show them a picture of what you are planning to build. The renderings of 360 are excellent. They are much more detailed than other programs, which should result in happy customer for you!

- Easy Changes – This is a feature that I really like about 360. When I’m designing an item, I am constantly changing the size of parts. In some programs, if you change the size of a part (or component) in your file, you’ll need to go back and manually resize all of the other related parts to your project. This can be time consuming depending on your project’s complexity. The nice thing about 360 is that you can easily resize parts and the logic within the program will help you automatically resize everything else while only requiring a couple inputs from the user. This is a significant feature in my opinion.

- Training – Due to the popularity of this software, there are quite a few videos available online. A basic search on Youtube will return numerous options for you. You can also find large Facebook groups that are willing to help as well as various forums. If you decide to use 360, I highly recommend looking for training videos made by Lars Christensen. He makes excellent videos that are very easy to follow.

SketchUp and Fusion are considered the two primary options for woodworkers when it comes to CAD designs. However, there are other options that you may prefer. One of those programs is called OnShape. It is considered an advantage software package, therefore I would not recommend it for someone new to just starting out. OnShape is a browser based program that offers free copies of their program to educators and students. Standard commercial copies cost $1500 per year.

If you are looking for an alternative to Fusion 360 that offers CNC integration, one such program to look at is Vectric’s Aspire. The target audience for Aspire is much more targeted towards users who do woodworking, engraving and jewelry design. The price for this software is $2,000, but there are lower priced options with a reduced features for $350 (VCarve Desktop) and $700 (VCarve Pro).

If you would like a more in-depth look at which software might be better for you to use as a woodworker, you can find an article I recently wrote here.

Conclusion

As you can there are plenty of options available on the market when looking to getting into CAD software to use for your woodworking needs. In my opinion, SketchUp and Fusion 360 will be plenty powerful enough for most woodworkers. If you think CAD design for your work is something you will get more and more involved with in the future, I’d recommend trying Fusion 360. Even though it has a steeper learning curve, it has several more features that may be of benefit to you later as your experience levels advance.

Many people like to use these woodworking design programs to organize their shops. This is done by getting the measurements of your large objects such as tables and saws and “placing” them in a replicated layout of your shop in the software. I covered the steps I used to get my shop organize in this recent article.