Buying your first wood lathe is an exciting experience. However, it can also quickly turn overwhelming. The dilemma I always run into when buying a piece of machinery is understanding what features are important. Even though I research every major purchase that I make, I always second guess my purchase. Not necessarily in the sense of “Should I have bought a _________?” Instead, my questioning is always “Should I have bought THIS specific machine?” My mind constantly turns wondering if perhaps I should have paid a couple hundred dollars more for a bigger size or a couple additional features.

I put this guide together to hopefully help you avoid these nagging questions. I hope after you read through this guide you can easily decide which features are most important to you and then go out and confidently buy the lathe that is right for you!

History

A wood lathe is one of the earliest forms of woodworking that has been discovered. Evidence of a lathe have been found in ancient Egypt dating back to 3 B.C. The wood lathe has changed in some ways over the past 2300+ years, however, the overall frame and structure of it are very much the same.

Today, lathes are used everyday from the hobbyist in their garage to large scale industrial factories. Lathes are used to make everything from table legs, gun stocks, watch components, baseball bats and architectural pieces for buildings. I highly recommend visiting the Louisville Slugger plant in Louisville, Kentucky if you are ever in the area. The tour they offer is exceptional. Their tour shows you how they got their starts making wooden bats for MLB players. Over the last decade or so, they have converted to CNC lathes that create bats specifically to a player’s requested preferences.

Base Types

The first thing that you need to decide when you are looking at wood lathes, is the size. Lathes come in 3 primary setups: bench top, mini-lathe and full scale. Odds are, you are going to go the route of a bench top or mini-lathe as full scale lathes are typically for woodworkers that have been using a lathe for many years.

- Bench top – These lathes are the smallest in scale and therefore take up the least amount of space in your shop. Just as the category states, these are made to sit on a bench in your work space. Even though these units are small in size, they are powerful and nice enough to produce very high quality work.

This size unit is perfect for beginners. The limited space requirements and cost make it perfect for someone to try to ensure wood turning is a hobby they want to pursue. Bench top units are fully capable of making quality pens, small table legs and bowls up to about 8″ in diameter depending on the specific brand unit you have. A very basic level unit can be purchased for as little as $250 and increase up to $500-600 depending on the features you want.

A bench top lathe will be limited in the length of material that it can hold. Most of these units can hold a piece of wood that is no more than 12-15″ inches in length. Don’t automatically discount a bench top model if you feel that you will need a machine to hold longer pieces! Some bench top lathes allow you to purchase extensions that connect to your base unit and allow you to use longer pieces of stock. This is a feature that I highly recommend because it allows you to keep your small foot print of space and enlarge it on an “as needed” basis. Getting a unit that has the extension capability may cost a bit more, but I think it’s worth it.

One feature you will likely come across that is specific to the bench top models is how you adjust the speed or RPM’s of the lathe. Generally a lathe is going to spin between 200 and 1400 RPM’s. The speed will be determined base on a number of factors such as your tools, the types of cuts you are making and most importantly the type of wood you are cutting.

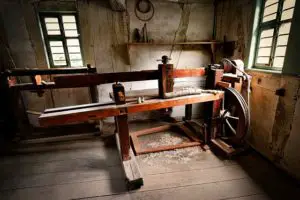

The lower cost bench top versions will require a manual speed adjustment. There are a few steps involved in order to complete the adjustment as these machines use a step cone pulley similar to the photo shown. Overall the process works very similar to the changing of gears on a 10 speed bike.

The user will need to turn the machine off and wait for it to come to a complete stop. Next, the pulley cover will need to be opened. Then, the user will need to work the belt onto a smaller pulley (to increase the speed) or a larger pulley (for a slower speed). This should not discourage you from getting a machine that has a manual speed adjustment. However, it’s important to know about it before purchasing one. If you are stuck deciding between two units, this may help make your decision easier.

- Mini Lathe – The next size lathe up from the bench top models are referred to as “mini lathes.” These are considerably bigger than the bench top models and for many decades were the smallest sized lathe you could buy – hence the reason the word “mini” is used to describe them.These machines are going to be much more stable that the bench top versions. Many times, these machines are built out of cast iron along with some steel parts which make them much heavier. The good thing about this is that it helps reduce the vibration and movement during cuts. Obviously, the negative is that they aren’t nearly as portable.

When you go to shop for a mini-lathe, odds are the stand will not be included in the price tag that you see. Many times, this is a separate cost from the machine. You have a couple options, you can purchase the base that is made for it, or you can build your own. It’s not uncommon to see mini-lathes bolted to a workbench. If you choose to build your own base, please ensure it is strong enough to handle the vibration and shaking that the lathe will create during use.Mini lathes will have a larger spindle and swing capacity which will allow you to work with larger stock. A user should be able to turn a bowl up to around 12” in diameter with a mini lathe. The spindle capacity is much greater on these units and can average up to 40″ or so. That’s about 2.5 times the capacity of a bench top unit. With this type length, you can easily cut full size table legs and even a baseball bat if you like.

Once you get to this level of unit, you will find the speed adjustments become much easier. You’ll be able adjust speeds on these units by turning a knob which will increase or decrease the electricity flowing to the motor. This adjustment can be made in a matter of seconds vs the manual adjustment which will take a few minutes to complete.

Due to the increase in size and the heavier materials that are used to make them, the prices for these units are much higher than those of the bench top versions. You can find base units starting around $800 and they can increase up to around $2,000.

- Full Size Lathe – Odds are if you are looking to purchase a full size lathe, you have years of experience working on one. I would not recommend a full size to someone who is new to wood turning. These machines can vary in size depending on the features and capabilities of what you are looking for. Some industrial lathes that are used to cut architectural pieces can accommodate spindles of up to 10 feet in length or more!

The swing capabilities are also much greater than what you will find on mini-lathes. These units can have capacities of 22″ or more depending on the model. With all these added capabilities, there is an increase in the amount of space and budget required to obtain one. Base models will tend to start around $3,000 and can go up to six figures or more if you are looking for computerized precision cutting.

Features

Below are some of the features that I feel are most important to consider when purchasing your new lathe.

- Swing Capacity – The swing capacity of a lathe is the largest diameter of stock that a lathe can hold. The physical limitation of this will be visible by looking at the distance between the spindle and the mounting rail under it.

- Spindle Capacity – The spindle capacity will determine how long of a piece you are able to turn on your lathe. A bench top lathe will probably accept material no longer than about 15″. Whereas a mini-lathe can easily go up to about 40″. If you are limited on space or budget at the time of purchasing your lathe but feel you may need a larger capacity, check to ensure the lathe accepts extensions! This will allow you to “add-on” to your machine in the future to accept longer pieces of stock.

- Motor Size – Lathes can come in a wide range of motor sizes. Some of the smalls ones will start out around 1/2 HP and can go on up to several HP’s. When deciding on what size motor you need, you’ll need to think about what it is you are wanting to cut. If you are doing something small like table legs, you can get by with something around 1/2 HP or 3/4 HP. However, if you can afford it, I would suggest getting something that is at least 1 HP, but again, it’s not required. You can still do nice work on smaller ones.

- Height – No matter what type of lathe you end up choosing, it’s important to take the height of the machine into consideration. More expensive machines will have adjustments available to make them comfortable to whatever level you desire.Bench top lathes and some mini-lathes don’t always come with bases unless you purchase them separately. In the case of a bench top lathe, it’s important to ensure you place the machine at a location that is the right height for the end user to avoid unnecessary fatigue. If your base is too high, your arms and shoulders will get tired reaching up to your stock. If it sits too low, your back will become sore from leaning over during turning. The general rule of thumb is that the lathe should come up to your elbows when standing next to it.

- Adjustable Headstock – The headstock of your lathe is the spindle that turns and is closest to your motor. This is the force that is causing your stock to turn on the lathe. If you are looking to turn large bowls, it’s important to look for a lathe that has an adjustable headstock. The nice thing about this feature is that you can turn the headstock away from it’s normal location, in some causes 180 degrees from it’s primary location. This allows you to more easily carve out the inside of the bowl you are turning. This feature will not be found on bench top lathes, but should become common one you get into the middle tier mini-lathes that are currently on the market.

Additional Tools

Sharpening Tools

When you are buying your first lathe, there are some additional expenses that you need to account for other than just the cost of the actual lathe machine. Of those “other” costs, the sharpening tools are probably the most expensive. You can expect to spend about $250 in tools for sharpening. In addition to learning how to use your new lathe, you will also want to make sure you learn how to properly sharpen your tools because they will dull as soon as you start using them. Working with dull tools will lead to poor cuts, longer work times and frustration.

The most expensive item related to sharpening tools that you will need is a bench grinder. A basic one with no stand can be found for as little as $50. I would recommend not buying the cheapest but instead getting a good quality brand because you will be using this tool considerably. I’d recommend picking up the 8″ Dewalt grinder for around $130. If you don’t have room on a workbench, you’ll want to pick up a stand for it as well and they run about $50.

The most expensive item related to sharpening tools that you will need is a bench grinder. A basic one with no stand can be found for as little as $50. I would recommend not buying the cheapest but instead getting a good quality brand because you will be using this tool considerably. I’d recommend picking up the 8″ Dewalt grinder for around $130. If you don’t have room on a workbench, you’ll want to pick up a stand for it as well and they run about $50.

The next item that you should pick up is a sharpening jig. I know some fellow woodworkers that have tried to skip buying this piece to save $100, but it makes life MUCH easier to have one. This one by Wolverine is great to work with and will make your sharpening process much quicker and more reliable. The jig will help hold your chisel at the correct angle and position to insure you are properly sharpening each and every time.

Cutting Tools

If you are purchasing your first wood lathe, I would recommend picking up a basic set of chisels to practice with. A good set that I’ve used before can be found at Harbor Freight. If you are lucky, you can find a 20% off coupon to bring the price down further. This is a good set of chisels that will allow you to learn cutting and sharpening without the stress of messing them up should you accidentally break one.

Safety

Please do not skip safety precautions on your new lathe. Having a piece of wood spinning at 1,000 RPM’s is not something that should be taken lightly. The most important safety device that you should purchase is a full face shield. This will help protect your face from getting hit with flying wood chips. There is a wide range of costs and features available, but at the very least you should pick up a basic one such as this one by Honeywell that runs about $20.

The next item on your list is one that you probably already have laying around your shop and that’s a pair of heavy duty gloves. Protecting your fingers from the chisel and spinning wood is a must!

Lastly, I would suggestion hearing protection as well as a respirator of some sort to protect your lungs from the dust that your machine will create. Lung and hearing protection are two of the most often overlooked areas in the shop. Long term exposure to loud noises and dust can have serious impacts down the road.

Other Considerations

If you have never used a wood lathe before, I’d highly recommend trying to get your hands on one before purchasing one. Nothing beats getting some actual time on a lathe to help you decide what features you may or may not like. Below are a few options that may help you try a lathe before buying.

Hackerspaces – These facilities can go by different names, but they are growing in popularity especially in major cities. Hackerspacers are community areas that have different tools that allow people to come in and work on their hobbies or crafts. The tool offering in these setups can vary from Woodworking to 3D printers and other setups. This would also be a good way to go about trying out different tools before actually purchasing them. There are usually membership costs to join and it’s common for their to be tiers that get you different levels of access.

Local Colleges – Another option is to look at your local colleges. Many times they offer woodworking courses thus requirement them to have a wood shop. Some offer access to these shops to the general public.

Local Woodworking Clubs – Most areas of the country have local or regional woodworking clubs. It wouldn’t hurt to reach out to these clubs to see if they know of any local workshops that offer availability to the public. There’s also a chance that if you join the club, a fellow woodworker would invite you over and lend some of their experience to someone just starting out.