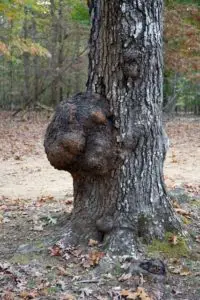

Tree burls are the ultimate example of Beauty and the Beast in woodworking. If you have ever seen a tree that has an unusual (sometime gross looking) growth on the side of it, you’ve probably seen a burl.

If you were standing in the forest and had to choose one tree to make a project from, it’s likely the tree with the burl would be the last log chosen. If you ask an experienced woodworker to choose from the same set of trees, it’s likely the one with the burl would be his first choice.

Burls, while unsightly on the outside, can produce amazing abstract designs within the grain on the inside of the tree. That’s what makes tree burls so prized by woodworkers. This beauty can only be created by nature.

What are tree burls, and how are they formed?

A burl, (also known as a bur, or burr), is an exterior growth on a tree, like a large bump

or knot. Burls are usually spherical in shape, and are like a “wart” on the tree. Others

can encompass the entire trunk.

They are formed in a similar way that an oyster forms a pearl. This is where we get the similarity of the name. A burl begins to form, when a tree has gone through some type of stress, as with an injury, fungus, insect infestation, or disease. Some scientists actually believe a theory that some trees are “generically predispositioned” to form burls, due to environmental conditions, or soil composition.

The process of creating burls is called: Hyperplasia. This is where the tree has a metabolic change of hormones, in a localized area, resulting in an abnormal growth pattern. This creates a very dense, irregular ring array, that is sought out by woodworkers worldwide.

Not all burls are found on the surface of the tree, but most are found in the root system. These can grow from a malignancy, or the most common reason is insect infestation. These aren’t usually discovered until the tree dies, and is uprooted.

Almost all the burls are covered in bark, even underground. They can grow to very large sizes, depending on the type of tree. Some have been recorded to be over 26′ wide, on the coast sequoia redwoods. Other trees can actually grow out of these large burls.

Though commonly confused with one another, tree burls are not the same as spalted wood. Spalted wood is created as a result of rot or decay that has begun to form within a piece of wood.

If you would like to learn more about spalted wood, take a look at this article I recently published!

What kinds of Trees grow Burls?

Many different trees can form burls, but the best ones are produced from; cherry, ash,

redwood, walnut, and maple. Oak trees also have burls, but most of the time they have

holes or rot, not yielding the best quality.

The rarest are from the Padauk trees of Southeast Asia, similar to the big leaf maple. They produce a burl known as the Amboyna. The bark is dark, but the sap is a creamy white, creating a beautiful result in the unusual pattern of the wood.

We need to add a note that burls are not know to kill trees, but may lessen the health and life-span of the tree.

What can you do with a Burl in Woodworking?

Because of the unique ring patterns produced by burls, they are coveted by  woodworkers to produce tables, counter-tops, bowls, veneers, artwork, wood watches, and even guitars! Various slabs of lumber can be milled, and made into furniture, or custom woodworking projects.

woodworkers to produce tables, counter-tops, bowls, veneers, artwork, wood watches, and even guitars! Various slabs of lumber can be milled, and made into furniture, or custom woodworking projects.

One large slab can make a magnificent table, or fireplace lintel. A round one can be put on a lathe, and turned, creating a bowl or vase of unique beauty.

Why are Burls so expensive?

The value of burls are based on the type of wood, a one of a kind pattern, and the condition of the wood. Layered burls are not as rare as the larger eyed ones. A good specimen can range from $25 to $200 for a single piece. Of course, a slab of considerable size can fetch as much as $500 or more.

Because of the interwoven and dense properties, burls are less likely to split. Making them an ideal piece of wood to work with. Burls are often cut into blocks, and sold. Going for around $200 per block.

Some of the most rare are: The King-wood, Tulip-wood. The Bois de rose burls, are ultra rare, as a rosewood all by themselves. It is the fact of their absolute uniqueness, that makes burls a treasured find.

How do you find Burls?

Keeping in mind as you search for burls, is the environment around the trees that produce them. Most burls are found on trees near water, or areas of frequent precipitation. Some burls will be obvious to see, and others like we mentioned before, are in the root system.

As you are walking, observe the roots and bark of the tree. If the roots are bent or rounded, instead of the typical snakelike pattern of a normal root, a burl may be responsible. Look for any unusual activity, such as injury, fungus, insects, or disease.  Take the time to search the limbs and branches, as not all burls will grow on the main trunk of the tree.

Take the time to search the limbs and branches, as not all burls will grow on the main trunk of the tree.

Branch burls are not as common as those that appear on the tree themselves. If areas are darker than the rest of the tree, these may also be signs of a burl. The bark of a burl, is of a rougher texture than the rest of the tree.

It would not be fitting if while we are discussing how to look for burls, if we did not mention the growing problem of poachers. Because burls are so rare, there are those who wish to have them, by any means possible. This practice is so bad, that parks in Northern California Redwood Forest, have at one time, been temporarily closed due to burl poachers.

The redwoods need burls to reproduce. The burl is actually a clone of these trees that are over 1,000 years old. They “sprout” a burl, to propagate before dying. When a reckless poacher takes a chainsaw and cuts a burl out of a tree, then the likelihood of that tree getting diseased, and a premature death is a result.

Law Enforcement is doing all they can with limited resources, to stop this cruel, illegal activity. It seems that this is happening at an increased rate. We are talking about an area that stretches from Northern California, into Oregon, some 2 million acres, of ancient forest. Over the last 150 years, almost 95% of this acreage is gone! Only the oldest and strongest remain.

Harvesting a Burl

We need to cover the proper procedure of harvesting a burl, before we go into the

cleaning process. The majority of the time, it is best to harvest the entire tree. As the

burl itself is not entirely on the surface, but can go all the way to the core or “pith” of the tree.

Cutting off just a portion, or “cow-pie”, is wasteful, and is damaging to the tree’s health. It is best to determine what kind of burl you have first, to get an idea how you want to use it, or what kind of project you plan to complete. Remember a layered burl,  is usually caused by an injury, and an eye burl is a probably a type of tumor, and is much more valuable. Each producing a totally different look to your wood.

is usually caused by an injury, and an eye burl is a probably a type of tumor, and is much more valuable. Each producing a totally different look to your wood.

If you have a “ball burl”, one that is part of a limb, it is best to cut 6” to 8” of the branch on each side, to protect it from cracking. The next procedure is to remove the bark. You will want to do this carefully, as not to damage the wood underneath.

Going at it with a chainsaw, may not be the best approach. Be sure to secure the log in a vice or clamping mechanism for safety. Try using a hacksaw, or pruning saw. You may also want to use a combination of a pealing spud, and a draw-knife.

Once the bark is removed, you may want to cut the burl into slabs or large blocks. When cutting a layered burl, go with the grain. If you have an eye burl, you can cut it in two ways to get the desired look. If you keep with the circular eye look, you cut in the direction to obtain the round eye. Cutting across the eye, will give you a starburst effect. Both ways are nice, so planning is important to get the best results.

Cleaning a Burl

Cleaning a burl is a careful procedure, as to secure the integrity of these rare items. The most common way to clean the raw burl is with warm soapy water, and a rag. Then let the wood DRY thoroughly. Don’t get in a hurry with burl wood, as this may take six months or more, depending on the size. Getting in a rush may warp, and twist the piece.

After the wood is dry, you can cut it into smaller blocks or parts. Once you shape your burl into the desired project, it is important to sand and seal it properly, with a polyurethane sealer.

To preserve your work of art for a lifetime, you can use linseed oil, and a dry lint free cloth. Be sure you keep the finished product away from direct sunlight, heat and air registers, as this tends to fade and dry the wood.

Burl wood may seem like a lot of trouble to mill, and prepare. However, this is another reason this type of wood is sought after, and a rare treasure. If you do have an opportunity to create, or own a unique piece of burl furniture, it is something you and your family, can enjoy for many years.